Izinyathelo ezijwayelekile zokucubungula isafire efektri yethu zimi kanje:

I-X-Ray NDT Crystal orientation apparatus

Okokuqala, sisebenzisa insimbi yokuqondisa eyikristalu ukuze sithole umumo wekristalu, bese sizomaka umumo njengezicelo zekhasimende.

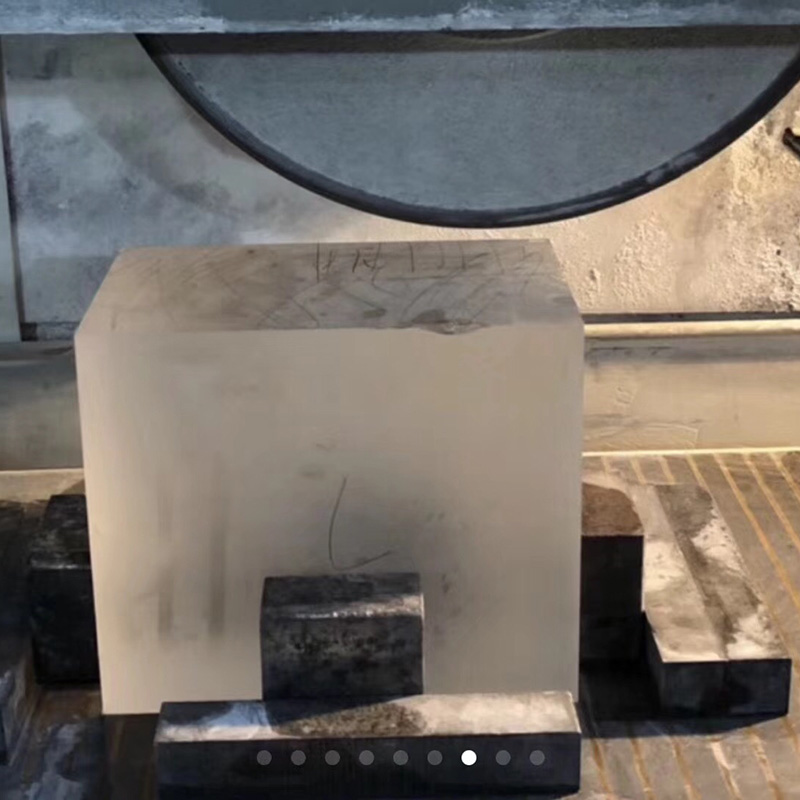

I-Sapphire Brick Cutting

Ngemuva kwalokho sizosika isitini sesafire, ukujiya kusondele kumkhiqizo oqediwe, kepha sigcine ukushuba kongqimba oludingekayo ukuze kugaywe nokupholishwa.

Imishini Yokuzungeza

Uma umkhiqizo wokugcina uyindilinga, sizobe sizungeza isikwele esisikiwe noma ishidi eliyindilinga eliyisicaba ukuletha ukuzungeza komkhiqizo ezingeni elidingekayo.

Igumbi Lokugaya

Ngemva kokuqeda wonke umsebenzi wangaphambilini ekubunjweni, sizocubungula ubuso bomkhiqizo kusukela ekugayeni,Kuye ngezinga lesidingo sokunemba komshini, sisebenzisa izinqubo ezimbili ezihlukene, ukugaya ohlangothini olulodwa noma ukugaya okukabili.

Umshini wokugaya nowokupholisha ohlangothini olulodwa

Ukugaya ohlangothini olulodwa kuthatha isikhathi eside futhi kulungele imikhiqizo enezidingo eziphezulu

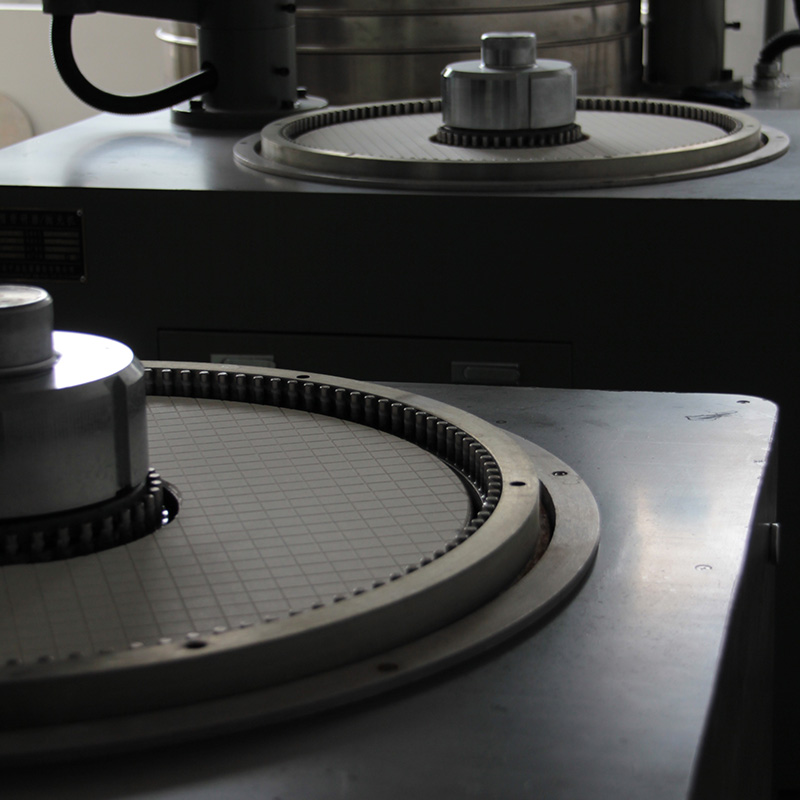

Umshini wokugaya onezinhlangothi ezimbili kanye nokupholisha

Ukucutshungulwa kokugaya okunezinhlangothi ezimbili kuyashesha kunokugaya ohlangothini olulodwa, kungaqeda ukugaya okubili ngesikhathi esisodwa, futhi ukufana komkhiqizo wokugaya okukabili kungcono kunokugaya uhlangothi olulodwa.

I-Manual Chamfering

I-Chamfering ingagwema ngempumelelo imiphumela emibi yokuwa konqenqema ekugayeni umkhiqizo kanye nokupholishwa ngenqubo yokwenza imishini.,Iphinde ivikele abasebenzi ekusikelweni lapho bethutha imikhiqizo.

Fine ukugaya inqubo workpiece

Ngemva kokuqeda inqubo yokuqala yokugaya, izongena kwesibili ukugaya, inqubo yokugaya kahle

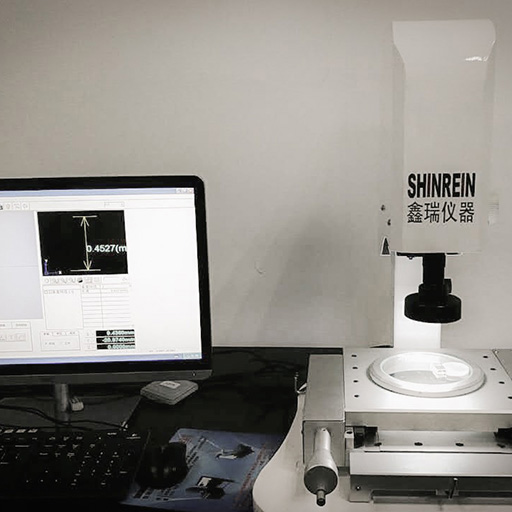

Ukukala Ubukhulu

Lapho inqubo yokugaya emihle isiphelile, sidinga ukukala ukujiya futhi siqiniseke ukuthi kusekubekezeleleni komkhiqizo ophelile. Ukuqina ngeke kushintshe ngesikhathi senqubo yokupholisha, ngakho-ke ubukhulu ngemuva kokugaya kahle kufanele kube ngaphakathi kwezidingo zomkhiqizo oqediwe.

Igumbi Lokupholisha

Uma izinga eliphezulu lomkhiqizo wokugaya kahle lingadlula ukuhlolwa kwabasebenzi bethu abanekhono, khona-ke lingena esigabeni sokugcina sokucubungula, ukupholisa. Ngokufanayo nokugaya, sizosebenzisa izindlela ezimbili ezihlukene zokupholisha kuye ngezidingo zekhwalithi yendawo yekhasimende.

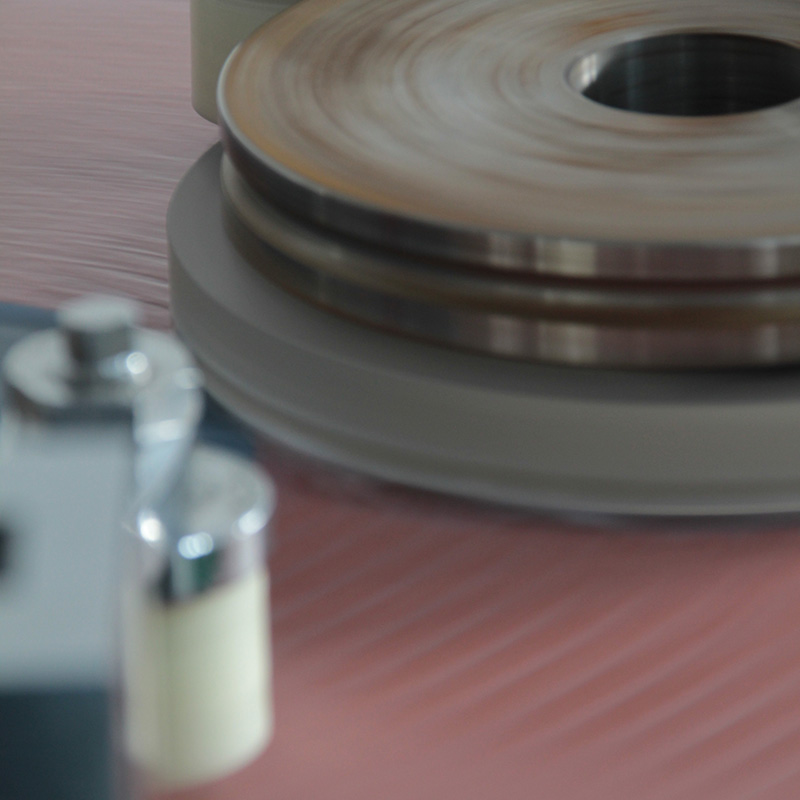

Igumbi Lokupholisha Kabili Kanye Nezisetshenziswa Zamanzi Ze-Ultrapure

Ukucwebezelisa okunezinhlangothi ezimbili kunganciphisa kakhulu isikhathi esidingekayo sokupholishwa, kuyilapho kususa izinyathelo zokucubungula zepuleti lokunamathisela, ngakho-ke kuvame ukusetshenziswa ezidingweni zekhwalithi engaphezulu aziphezulu, kodwa inani lokucubungula likhulu.

Ukupholisha Kohlangothi Olulodwa

Emikhiqizweni enezidingo zekhwalithi ephezulu, kuvame ukudingekile ukucubungula uhlangothi olulodwa emshinini wokupholisha ohlangothini olulodwa ukuze kuncishiswe okuguquguqukayo okudingeka kulawulwe enqubweni yokucubungula, futhi izinhlobo zangaphezulu ezinembayo ngokuvamile zidinga ukulungiswa futhi kusetshenzwe ngokuphindaphindiwe ukuze kutholwe, okuphinde kunqume ukuthi kungani intengo yemikhiqizo enembayo iphezulu kakhulu kunokunemba okuvamile komkhiqizo

Ukuhlola Ubukhulu

Ngemva kokucubungula nokuhlanza, umkhiqizo uthunyelwa esikhungweni sethu sokuhlola ikhwalithi ukuze uthole uchungechunge lokuhlolwa ukuze kuqinisekiswe ukuthi umkhiqizo ophelile uhlangabezana nezidingo zokuklama kwekhasimende. Impela, ukuhlolwa komkhiqizo oqediwe lapha akumele zonke izinqubo zethu zokuhlola nezindlela zokuqinisekisa ikhwalithi, ukuhlolwa komkhiqizo kuzosebenza kuyo yonke inqubo.,ikakhulukazi njengobukhulu, ubuyindilinga, ukuhambisana, ukuma, i-engeli, ukucaba kwendawo.

Ukuhlola Ikhwalithi Yobuso

Sisebenzisa izibani zokuhlola ezijwayelekile nezibonakhulu ukuze sihlole imihuzuko namachashaza ebusweni bomkhiqizo.

Ukuhlola I-Surface Flatness

Ukucaba kwendawo nokuhambisana komkhiqizo kuzotholwa kusetshenziswa i-laser interferometer